Computer Numerical Control (CNC) which is a method of CNC machining has revolutionized manufacturing and engineering in the last few decades. CNC is a method that combines digital technology and traditional machining to make high-precision components in a variety of industries. This article examines the mechanics, benefits and diverse applications of CNC machining to highlight the impact it has on engineering technology of the present.

The Mechanics of CNC Machining

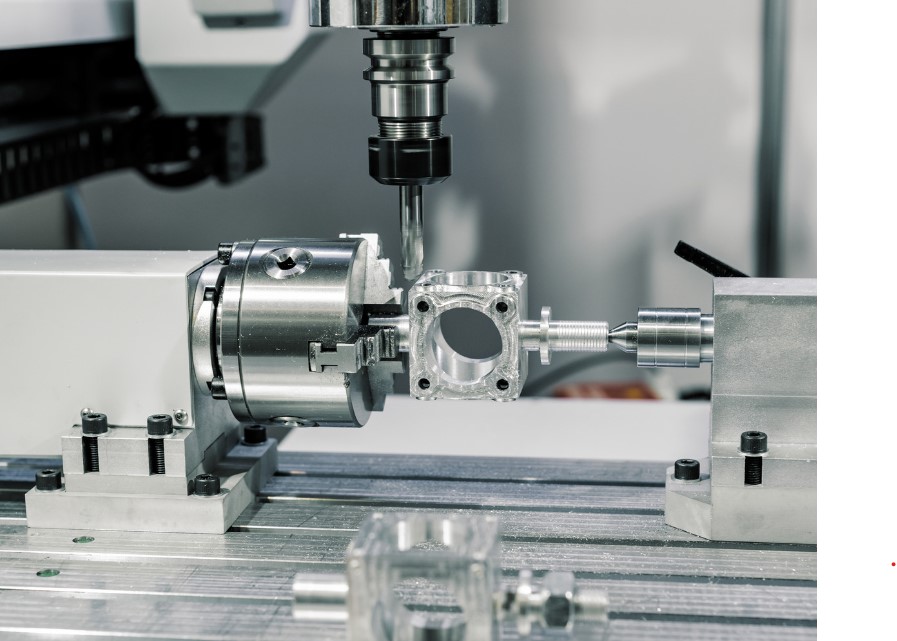

CNC machining is a subtractive manufacturing process which means that it removes the substance from a solid block or workpiece to create the desired shape. The process is controlled by computer software that has been pre-programmed and controls the movements of the machinery. The code used for CNC machines varies depending on the type of machine and how complex the component is that is being produced. But the basic principle remains the exact the same: a high-speed cutter cuts material carefully for the final product.

The accuracy of CNC machine is among the most important benefits. The digitalization process allows for the production of consistent and precise. This reduces the chance of human error while maintaining consistency across batches. This level is critical in industries like medical devices, aerospace, and manufacturing for automobiles, where minor deviations could lead to serious consequences.

The role of digitalised computers in CNC Machine Operations

CNC precision and efficiency are a result from the integration of digital technologies. CNC machines are controlled by specialized software that automates the entire manufacturing process. The software converts computer-aided drawings (CAD) into an exact set of instructions that are executed by the CNC machine to make the piece. The instructions define everything from the speed and direction of the cutting tool, to the angle and depth of each cut.

In larger industrial facilities on a scale, computers can be connected directly to CNC machines. This allows for seamless communication and control. This integration allows constant adjustments in real time and monitors to ensure maximum performance and decrease time to repair. Automating CNC machineries allows for continuous operation. This increases productivity and reduces time to market.

The Advantages of CNC Machining

CNC machining offers numerous advantages over traditional manufacturing techniques. One of the biggest advantages is the ability to create intricate and complex components with a high degree of precision. The accuracy of CNC machines eliminates the need for manual adjustments and Rework, which reduces waste while increasing efficiency. In addition, CNC machines can operate constantly, which makes them ideal for high-volume production runs.

Another advantage is the flexibility of CNC machining. One machine can make various types of components through merely changing the program. CNC machine is able to be modified which makes it appropriate for prototyping as much in mass production. This allows manufacturers to quickly respond to market demands changes.

Automating CNC machineries improves safety at work. In reducing the requirement for manual intervention, the chance of injuries and accidents are decreased. In addition, the high-quality of CNC-machined products improves durability and efficiency, contributing to the satisfaction of the customer and enhancing the reputation of the brand.

Industries benefiting from CNC Machining Services

In a range of industries CNC machining has proved to be highly efficient flexible, precise, and accurate. CNC machines are used in the aerospace sector for manufacturing crucial components that must meet the strict requirements for safety and performance. CNC machines are employed in the medical device industry to produce complex implants and surgical instruments where accuracy is key.

The automotive industry utilizes CNC machines to create components for engines, transmission parts, and intricate exterior and interior features. Electronics also benefit from CNC Machining, which is able to create small, intricate components for consumer electronic devices and communication equipment. The art and jewelry industries make use of CNC technology to produce intricate designs and bespoke pieces.

The Future of CNC Machining

As technology continues to advance and improve, the capabilities of CNC machines are expected to expand further. Technologies like multi-axis machining, additive manufacturing integration, and the use of advanced materials will continue to push the limits of what’s possible with CNC technology. Additionally, machine-learning and AI will increase CNC machine efficiency.

CNC machining is a powerful tool that has impacted engineering and manufacturing in the present. It is a tool that offers unmatched precision, flexibility, and efficiency. The capability to produce complicated parts with high accuracy makes it an indispensable instrument for a range of industries. CNC machining, as technology advances is expected to remain an essential component of manufacturing’s future.